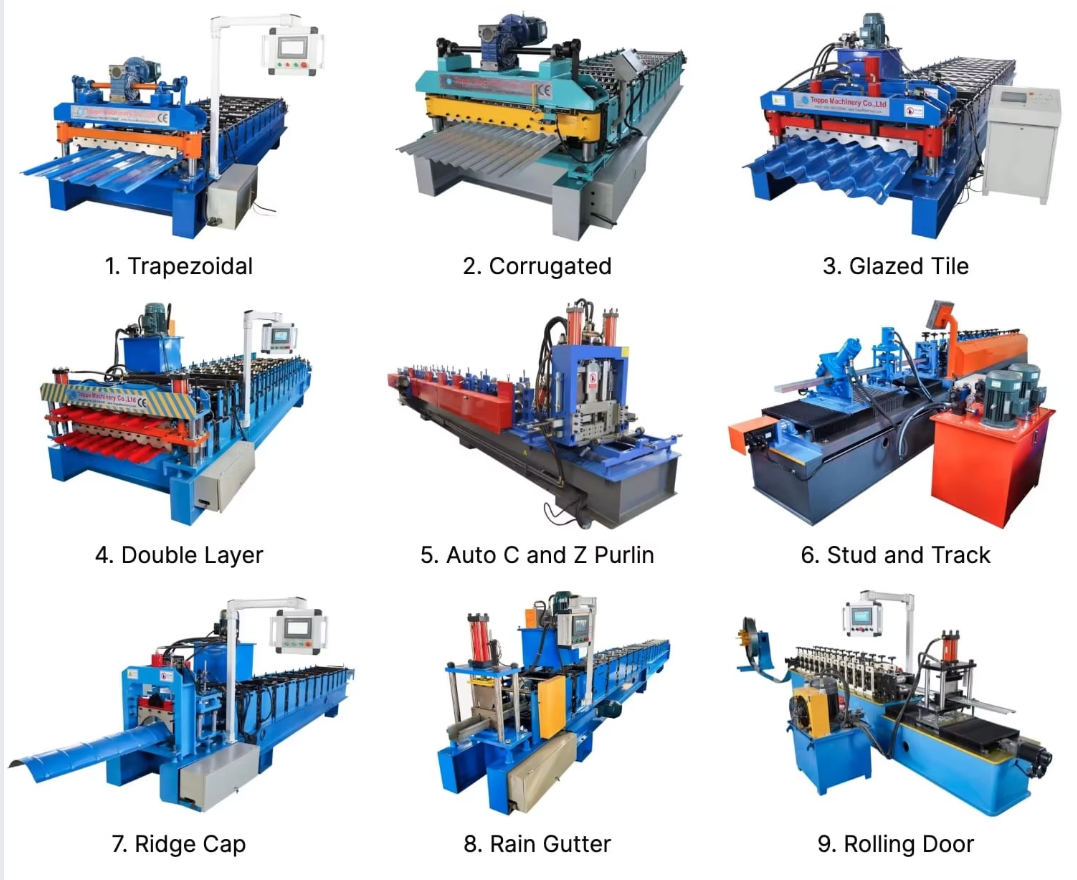

- Trapezoidal Machine

- Corrugated Machine

- Glazed Tile Machine

- Double Layer Machine

- CZU Purlin Machine

- Ridge Cap Machine

- Floor Decking Machine

- Rolling Door Machine

- Fence Machine

- Embossing Machine

- Standing Seam Machine

- Cut To Length And Slitting Line

- Guard Rail Machine

- Decoiler And Stacker

- Stud And Track Machine

- Gutter And DownPipe

- Curving Machine

- Cladding Panel Machine

- Corollary Equipment

- Trapezoidal Machine

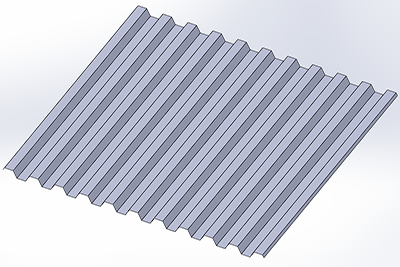

- Corrugated Machine

- Glazed Tile Machine

- Double Layer Machine

- CZU Purlin Machine

- Ridge Cap Machine

- Floor Decking Machine

- Rolling Shutter Door Machine

- Palisade Fence Machine

- Embossing Machine

- Standing Seam Machine

- Cut To Length And Slitting Line

- Guard Rail Machine

- Decoiler And Stacker

- Stud And Track Machine

- Gutter And DownPipe

- Curving Machine

- Cladding Panel Machine

- Corollary Equipment

- Other

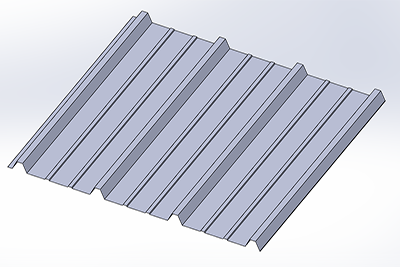

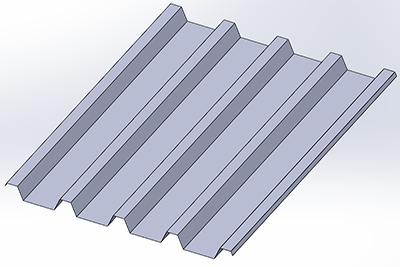

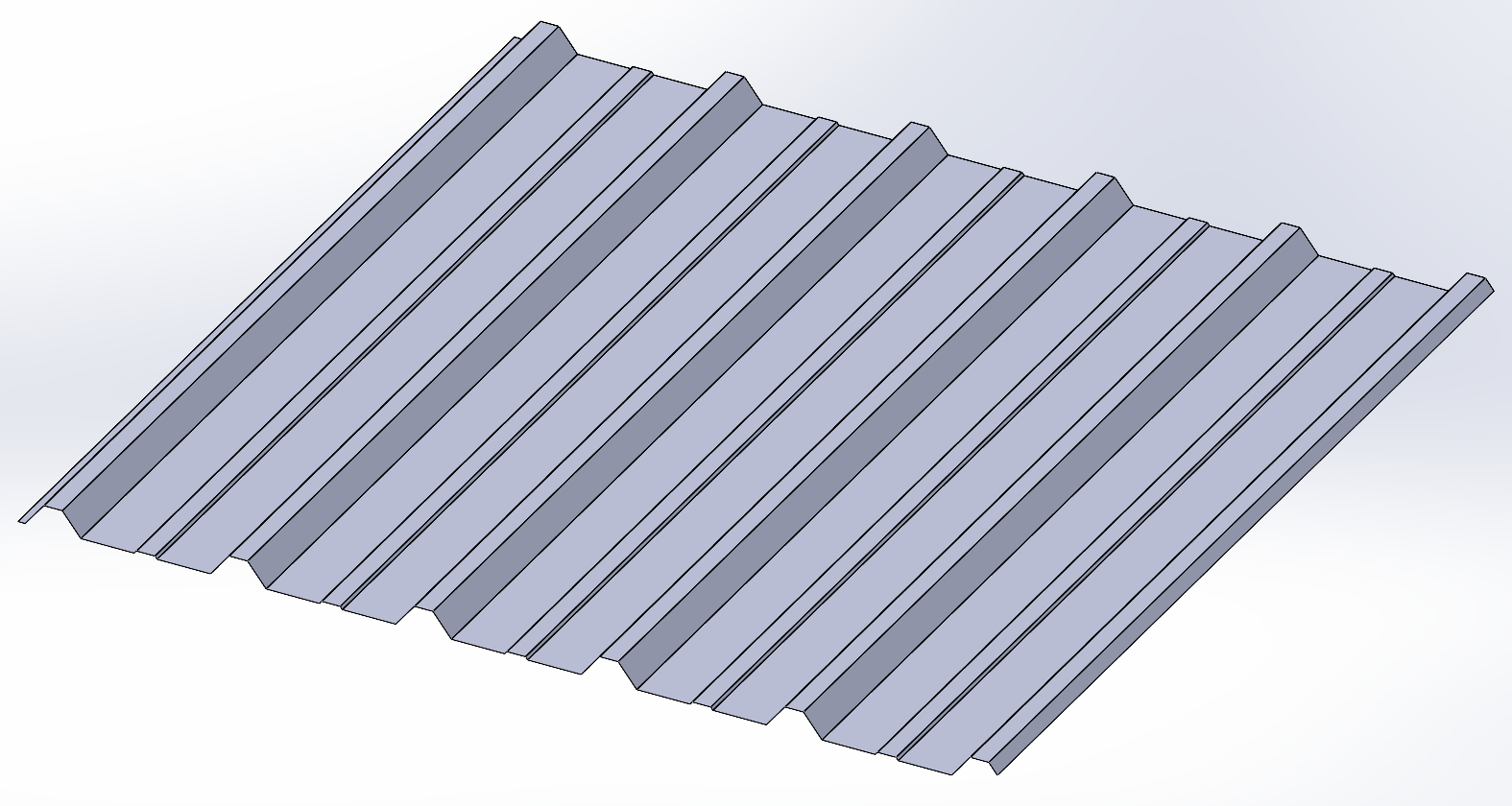

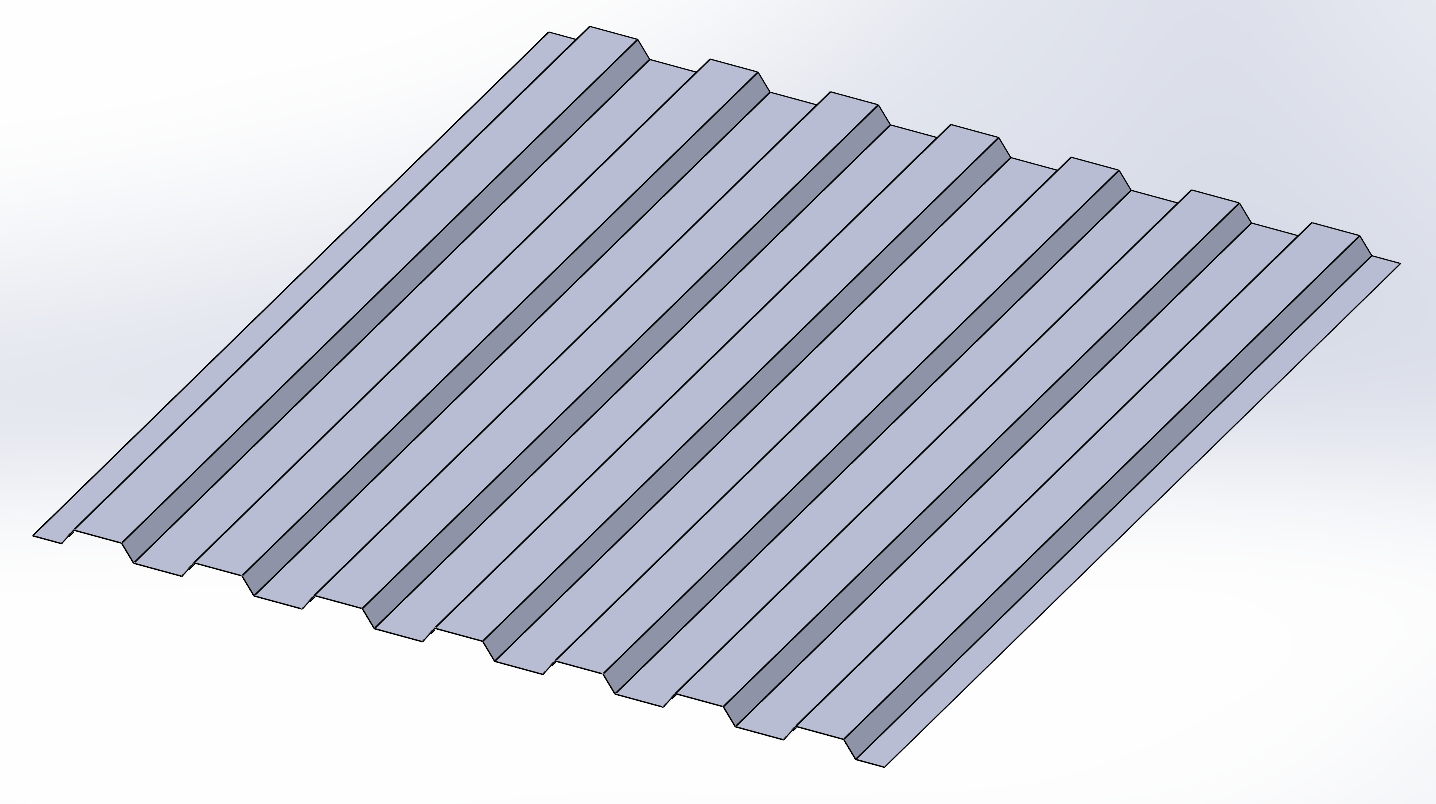

Industrial Trapezoidal Roof Panel Roll Forming Machine

The TOPPO trapezoidal panel forming machine is specially designed for fabricating roofing sheets with trapezoidal profiles. It processes metal coils into finished roof panels automatically, with high accuracy and efficiency. This model is perfect for steel structure building manufacturers, contractors, and metal product exporters.

Technical Specifications and Features:

Profile Type: Trapezoidal roofing panels

Raw Material: Galvanized Steel, PPGI, Aluminum

Material Thickness: 0.3–0.8 mm

Input Coil Width: 1000–1250 mm

Effective Panel Width: 836–1050 mm

Forming Speed: 12–15 m/min

Roller Stations: 16–20

Roller Shaft Diameter: 75 mm

Roller Material: GCr15 with hard chrome plating

Drive Type: Chain or Gearbox

Main Motor Power: 7.5 kW

Hydraulic Power: 4.0 kW

Cutting System: Hydraulic cutting, post-cut type

Cutting Blade Material: Cr12Mov, heat-treated

Cutting Accuracy: ±1 mm

PLC System: Siemens or Delta

Touch Screen: HMI interface for easy operation

Power Supply: 380V/50Hz/3Phase (customizable)

Machine Structure: 300H steel welded frame

Side Panel Thickness: 16 mm

Safety System: Emergency stop + protective covers

Output Table: Manual/auto stacking available

Uncoiler: Optional 5T hydraulic/manual

Machine Dimensions: Approx. 8500 x 1500 x 1500 mm

Machine Weight: 5.5–6.5 tons

Color: Blue/Orange (customizable)

Noise Level: ≤75 dB

Tool Life: >10 years

Production Line Type: Fully Automatic

OEM Service: Available

Warranty: 12 months

After-sales Support: Remote guidance, videos, parts

Operator Requirement: 1–2 person(s)

Installation Support: Engineer available

Maintenance: Easy access with low cost

Storage Temperature: -20℃ to +55℃

Surface Treatment: Rust-resistant coated body

Packaging: Steel frame + plastic film

Lead Time: 30 days after deposit

Market Coverage: Asia, Middle East, Africa, Europe

Certifications: CE, ISO

Additional Information:

This trapezoidal roll forming machine is engineered to produce flawless roofing sheets that meet global standards. With its fully digital PLC automation system and precision cutting, it eliminates human error and reduces material waste. Whether you're upgrading your factory or starting a new line, this is a cost-effective investment with long-term returns.

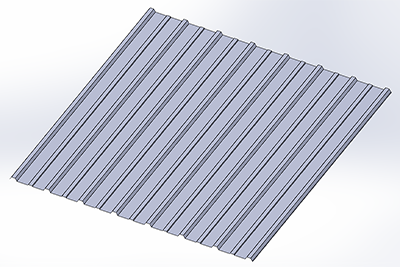

Drawing(Partial display)

Layout

.png)

Application

End Product

Roofing panel roll forming machine Description

This Trapezoidal Roof Panel Roll Forming Machine is a fully automatic equipment specially designed for manufacturing steel trapezoidal roofing sheets. With high forming speed, precise cutting, and intelligent control, it offers an ideal solution for construction material producers. The equipment is easy to operate, durable, and provides excellent production efficiency, suitable for both small workshops and large industrial manufacturing lines

Catalog

Roofing panel roll forming machine Description

Roofing system roll forming machine is used in an extensive range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile panel, step tile, glazed tiles, metal deck panel, standing seam panel, K span panel and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

The normal thickness range of roof panel roll forming machine is 0.2mm-0.8mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave.

The standard machine speed can reach about 20M/min, if the capacity is big, we can make the machine speed which can reach 25-30M/min. And some customer they require the thickness of the roofing sheet is 1.2mm, it is ok too. If you want learn more of this kind of machine, choosing our company is your best option.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-