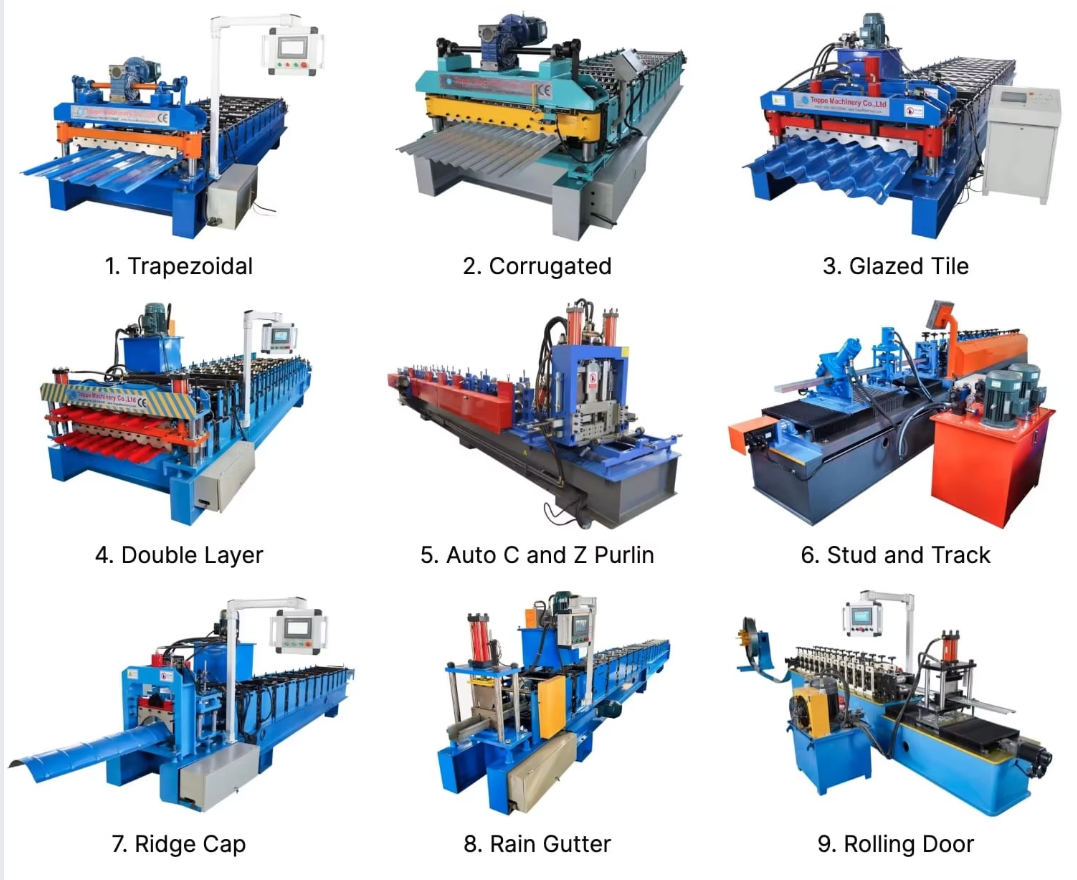

- Trapezoidal Machine

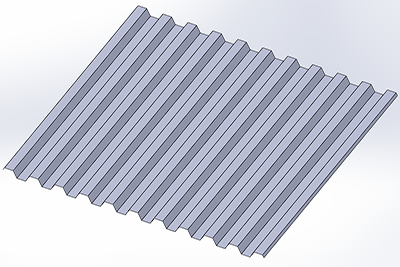

- Corrugated Machine

- Glazed Tile Machine

- Double Layer Machine

- CZU Purlin Machine

- Ridge Cap Machine

- Floor Decking Machine

- Rolling Door Machine

- Fence Machine

- Embossing Machine

- Standing Seam Machine

- Cut To Length And Slitting Line

- Guard Rail Machine

- Decoiler And Stacker

- Stud And Track Machine

- Gutter And DownPipe

- Curving Machine

- Cladding Panel Machine

- Corollary Equipment

- Trapezoidal Machine

- Corrugated Machine

- Glazed Tile Machine

- Double Layer Machine

- CZU Purlin Machine

- Ridge Cap Machine

- Floor Decking Machine

- Rolling Shutter Door Machine

- Palisade Fence Machine

- Embossing Machine

- Standing Seam Machine

- Cut To Length And Slitting Line

- Guard Rail Machine

- Decoiler And Stacker

- Stud And Track Machine

- Gutter And DownPipe

- Curving Machine

- Cladding Panel Machine

- Corollary Equipment

- Other

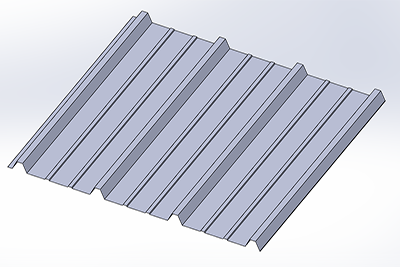

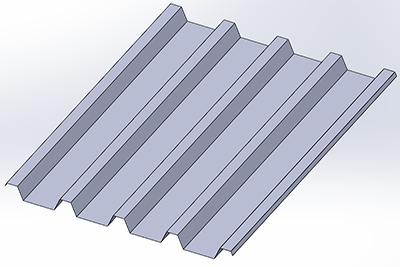

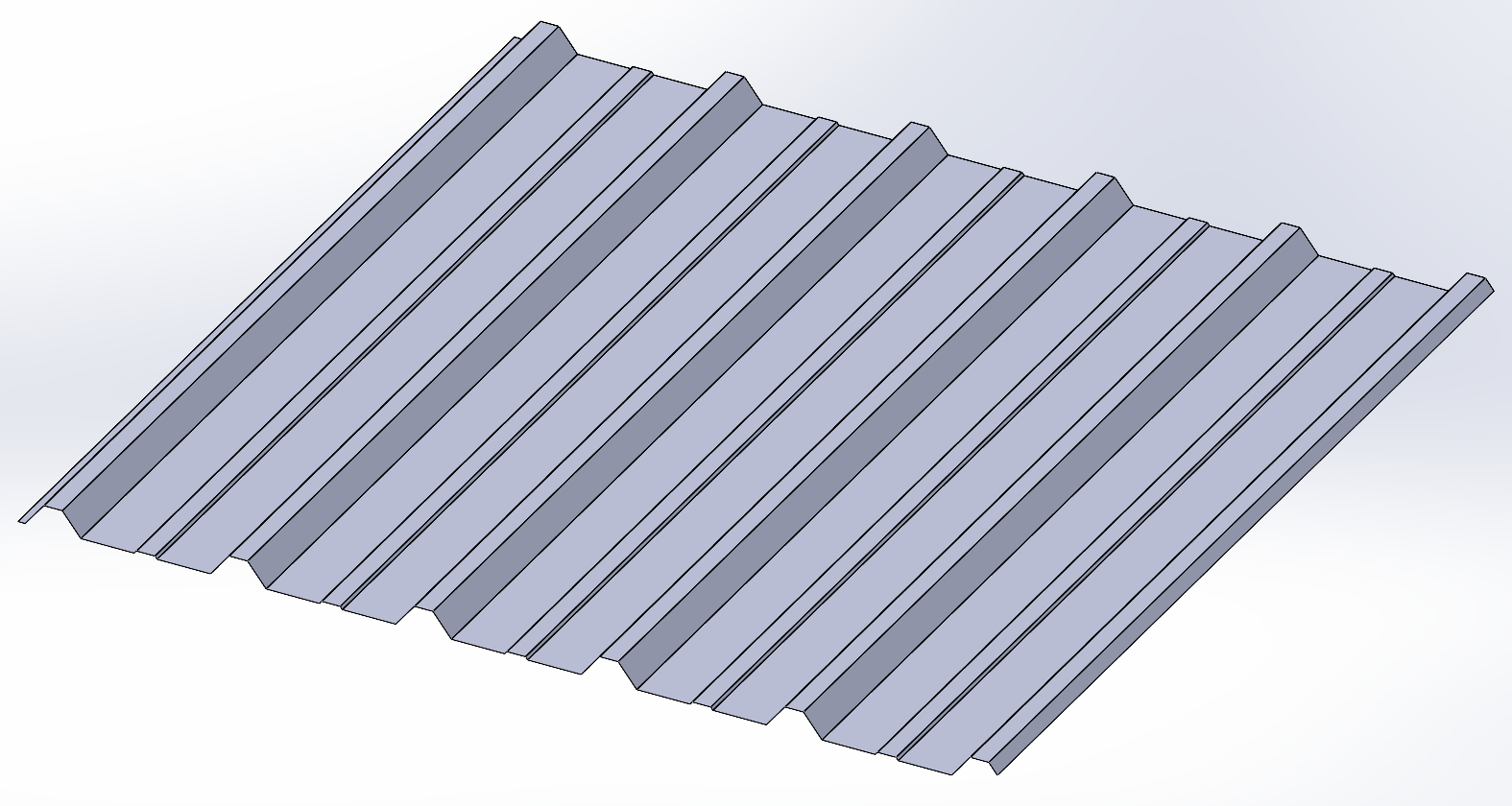

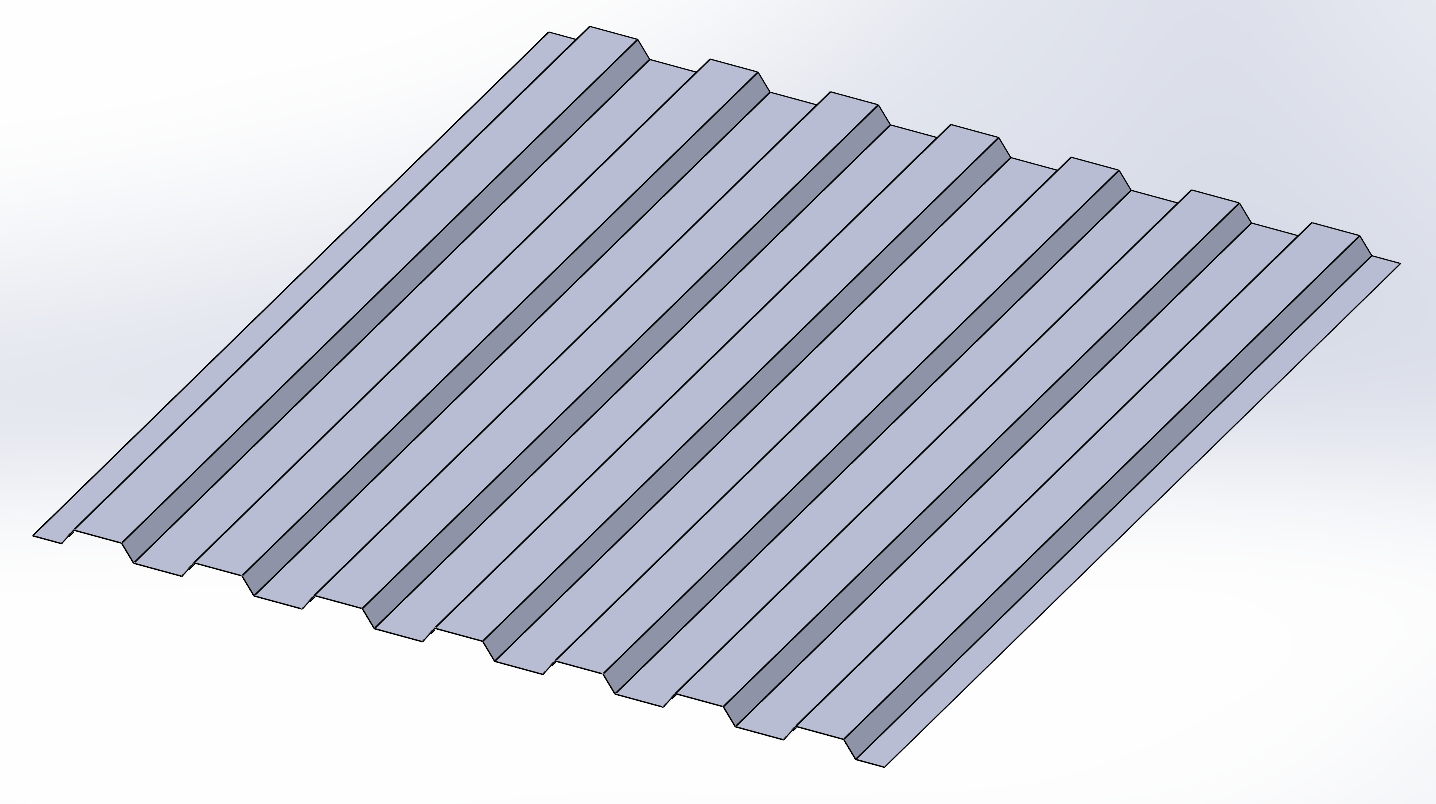

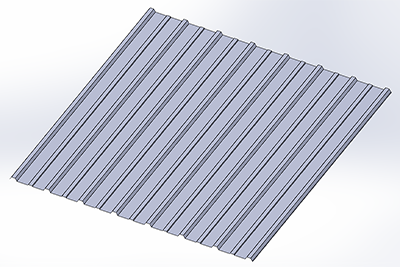

Product Overview

Type: Trapezoidal Roofing Roll Forming Machine

Input Material: Color steel, galvanized steel, galvalume, aluminum

Material Thickness: 0.3–0.8 mm

Input Coil Width: 1000 mm / 1250 mm

Effective Panel Width: 836 mm / 1050 mm (varies by profile)

Profile Shape: Deep rib trapezoidal

Roller Stations: 18 rows

Rollers: GCr15 steel, heat-treated and chrome-coated

Shaft Diameter: 75 mm precision-turned solid shaft

Transmission: Gearbox or chain drive

Main Motor Power: 7.5 kW

Hydraulic Power: 4.0 kW

Cutting Blade: Cr12Mov steel, quenched

Cutting Method: Hydraulic post-cutting

Cutting Tolerance: ±1 mm

Control System: PLC + touch screen (Delta/Siemens)

Operation Language: English/Chinese/optional

Speed: 10–18 m/min depending on profile

Voltage: 380V/50Hz/3Phase (or customized)

Weight: Approx. 6.0 tons

Machine Dimensions: 9.0 × 1.5 × 1.6 m

Uncoiler: Hydraulic or manual, 5-ton capacity

Output Rack: 3-meter passive run-out table

Coil Inner Diameter: 508 mm

Coil Outer Diameter: ≤1300 mm

Max Coil Weight: 5000 kg

Lubrication System: Manual greasing (automatic optional)

Safety Features: Emergency stop, covers, limit switches

Finish Quality: Smooth and uniform profile, no scratches

Usage Environment: Indoors, temperature 0–40°C

Dust Protection: Electrical components with IP54 rating

Production Workflow: Coil → Leveling → Roll forming → Cutting → Collecting

Certification: CE certified

Color: Blue / Custom RAL code on request

Application: Roofing systems for factories, logistics parks, farms

Machine Color: Industrial blue (customizable)

Maintenance: Low maintenance, easy to clean

Support: Online training and operation guide

Installation: Engineer available for overseas installation

Warranty: 24 months for core components

Optional Features: Inkjet printer, auto stacking system

Noise Level: Less than 80 dB

Auto Counting: Integrated piece counter

Profile Adjustment: Interchangeable roller molds optional

Why This Model?

Engineered for heavy-duty forming, this machine is suitable for long-span trapezoidal sheet production with minimal error. With its high-speed capability, durable frame, and intelligent control system, it delivers stable performance for high-output environments.

Working Flow

Coil feeding → Sheet guiding → Roll forming → Hydraulic shearing → Finished panel output → Stacking.

Drawing(Partial display)

Layout

.png)

Application

End Product

Roofing panel roll forming machine Description

This Trapezoidal Roof Panel Roll Forming Machine is a fully automatic equipment specially designed for manufacturing steel trapezoidal roofing sheets. With high forming speed, precise cutting, and intelligent control, it offers an ideal solution for construction material producers. The equipment is easy to operate, durable, and provides excellent production efficiency, suitable for both small workshops and large industrial manufacturing lines

Catalog

Roofing panel roll forming machine Description

Roofing system roll forming machine is used in an extensive range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile panel, step tile, glazed tiles, metal deck panel, standing seam panel, K span panel and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

The normal thickness range of roof panel roll forming machine is 0.2mm-0.8mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave.

The standard machine speed can reach about 20M/min, if the capacity is big, we can make the machine speed which can reach 25-30M/min. And some customer they require the thickness of the roofing sheet is 1.2mm, it is ok too. If you want learn more of this kind of machine, choosing our company is your best option.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-