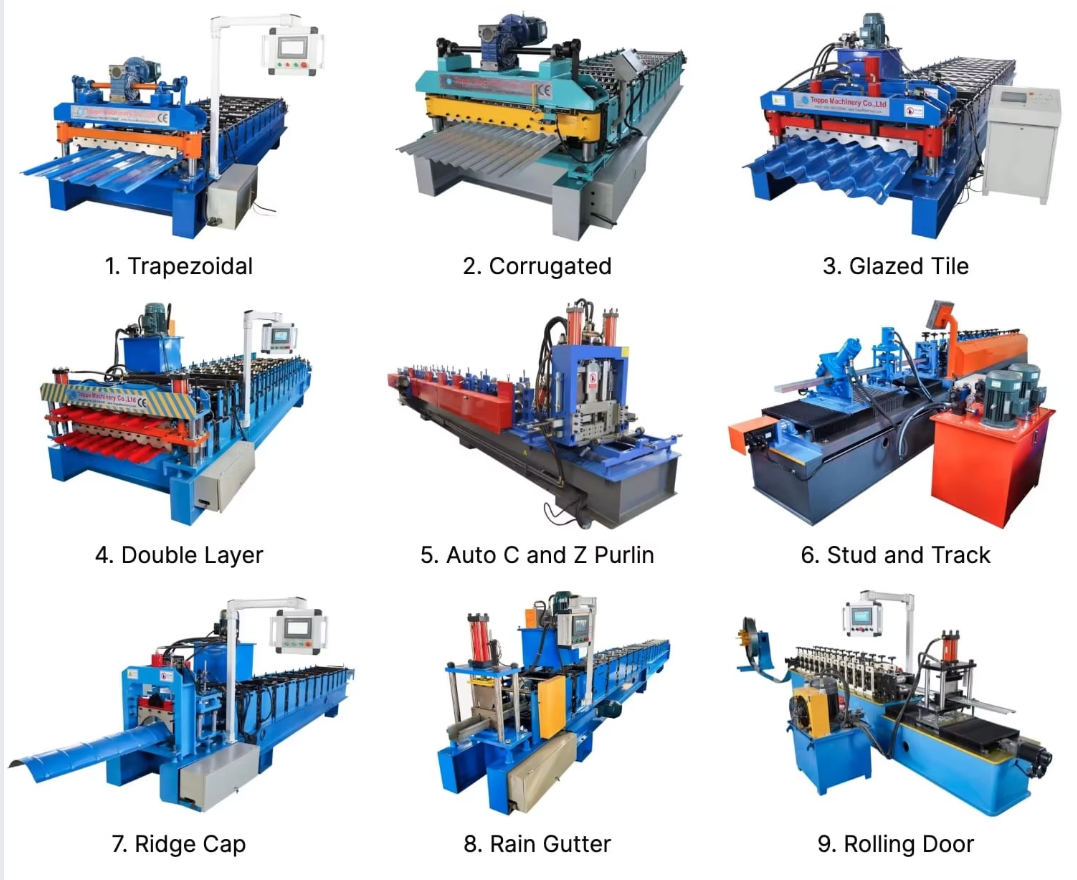

- Trapezoidal Machine

- Corrugated Machine

- Glazed Tile Machine

- Double Layer Machine

- CZU Purlin Machine

- Ridge Cap Machine

- Floor Decking Machine

- Rolling Door Machine

- Fence Machine

- Embossing Machine

- Standing Seam Machine

- Cut To Length And Slitting Line

- Guard Rail Machine

- Decoiler And Stacker

- Stud And Track Machine

- Gutter And DownPipe

- Curving Machine

- Cladding Panel Machine

- Corollary Equipment

- Trapezoidal Machine

- Corrugated Machine

- Glazed Tile Machine

- Double Layer Machine

- CZU Purlin Machine

- Ridge Cap Machine

- Floor Decking Machine

- Rolling Shutter Door Machine

- Palisade Fence Machine

- Embossing Machine

- Standing Seam Machine

- Cut To Length And Slitting Line

- Guard Rail Machine

- Decoiler And Stacker

- Stud And Track Machine

- Gutter And DownPipe

- Curving Machine

- Cladding Panel Machine

- Corollary Equipment

- Other

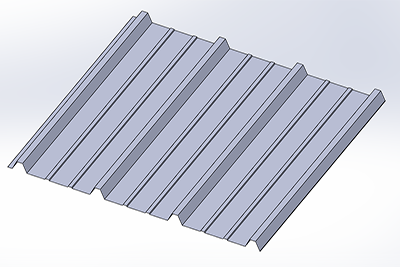

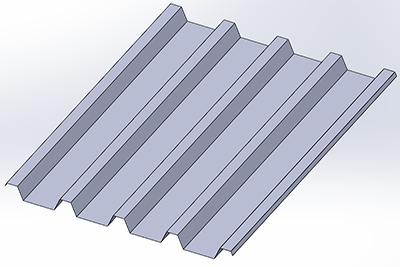

Trapezoidal Roof Panel Roll Forming Machine - Product Description

Machine Type: Trapezoidal roof panel roll forming machine

Application: Production of metal roofing and cladding panels

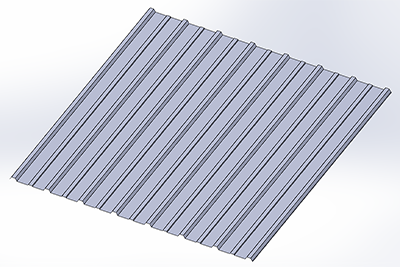

Panel Shape: Trapezoidal profile

Suitable Materials: Color steel, galvanized sheet, aluminum coil

Material Thickness: Approx. 0.3–1.0 mm

Forming Stations: Multiple roll forming stands

Cutting Type: Hydraulic post-cutting or pillar shear system

Control System: PLC control with touch screen

Drive Type: Motor + chain or gear drive

Shaft Material: Hardened steel (e.g. 45#)

Roller Material: Hardened steel or alloy steel

Frame Structure: Welded steel base

Color: Industrial blue finish

Hydraulic System: Hydraulic pump with cylinders

Output Table: Discharge stand or support system

Voltage: 380V / 50Hz / 3 Phase (customizable)

Main Motor Power: Around 5.5 kW

Production Speed: Up to 8–12 m/min

Cutting Precision: ±2 mm

Language: Bilingual (English/Chinese), customizable

Transmission: Standard industrial chain or gear

Shaft Diameter: Typically Ø70 mm

Lubrication: Grease or oil, manual or automatic

Machine Length: Long-forming line configuration

Weight: Heavy-duty machine (several tons)

Base Dimensions: Custom width/length/height

Safety Guard: Protective cover or fencing

Adjustment Mode: Manual, servo, or mechanical

Feeding Device: Guided feeder

Decoiler: Equipped with manual or hydraulic decoiler

Bearings: Roller or ball bearings

Cooling: Fan-cooled or oil-cooled hydraulic system

Installation Method: Ground-mounted with anchor bolts

Electrical Cabinet: Independent control box

Wiring: Neat cable arrangement

Start/Stop: Push buttons, emergency stop, touchscreen

Fine Tuning: Handwheel, servo, or mechanical adjustment

Testing Function: Trial run feature

After-Sales: Technical support and spare parts service

Drawing(Partial display)

Layout

.png)

Application

End Product

Roofing panel roll forming machine Description

This Trapezoidal Roof Panel Roll Forming Machine is a fully automatic equipment specially designed for manufacturing steel trapezoidal roofing sheets. With high forming speed, precise cutting, and intelligent control, it offers an ideal solution for construction material producers. The equipment is easy to operate, durable, and provides excellent production efficiency, suitable for both small workshops and large industrial manufacturing lines

Catalog

Roofing panel roll forming machine Description

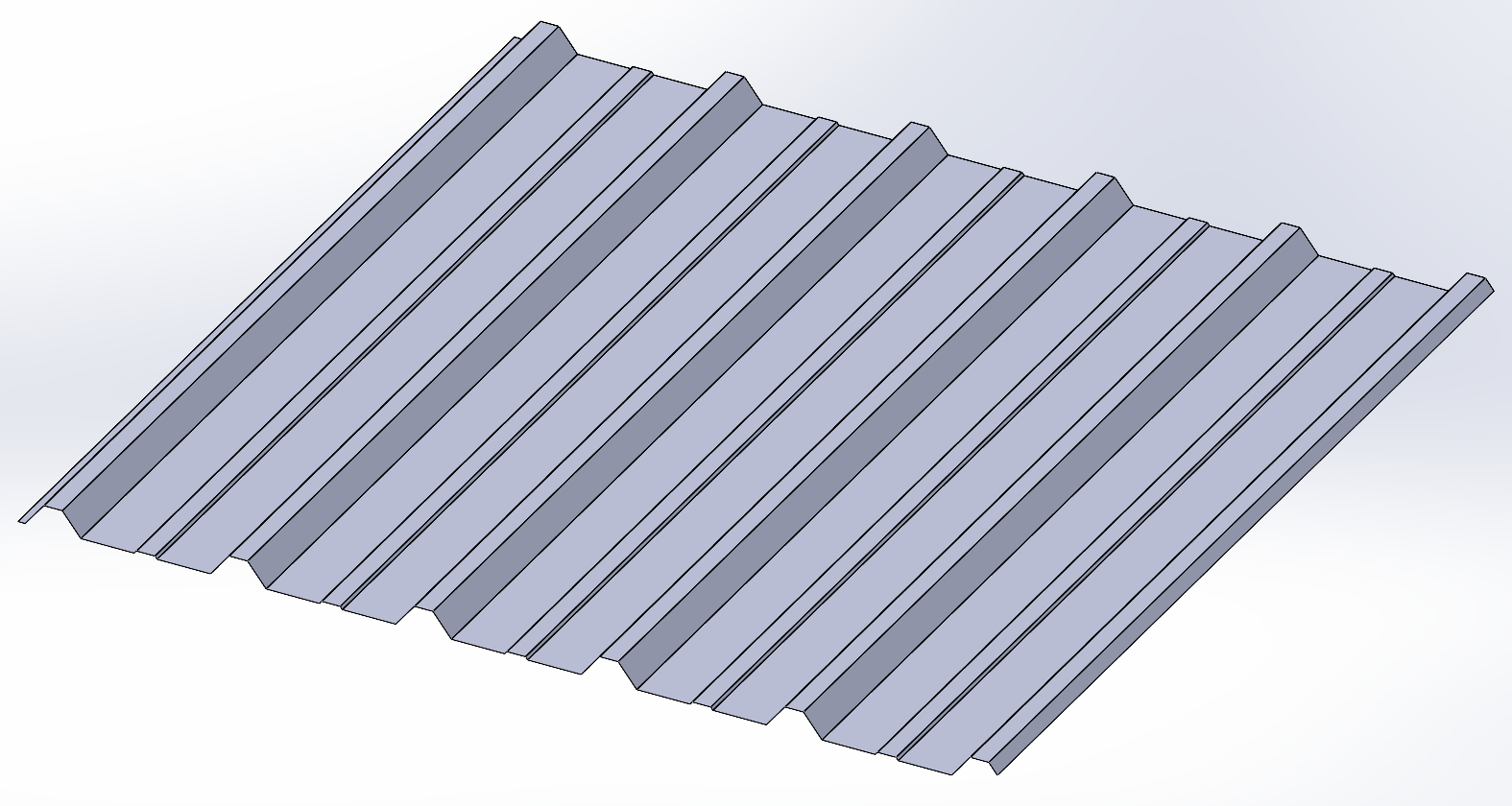

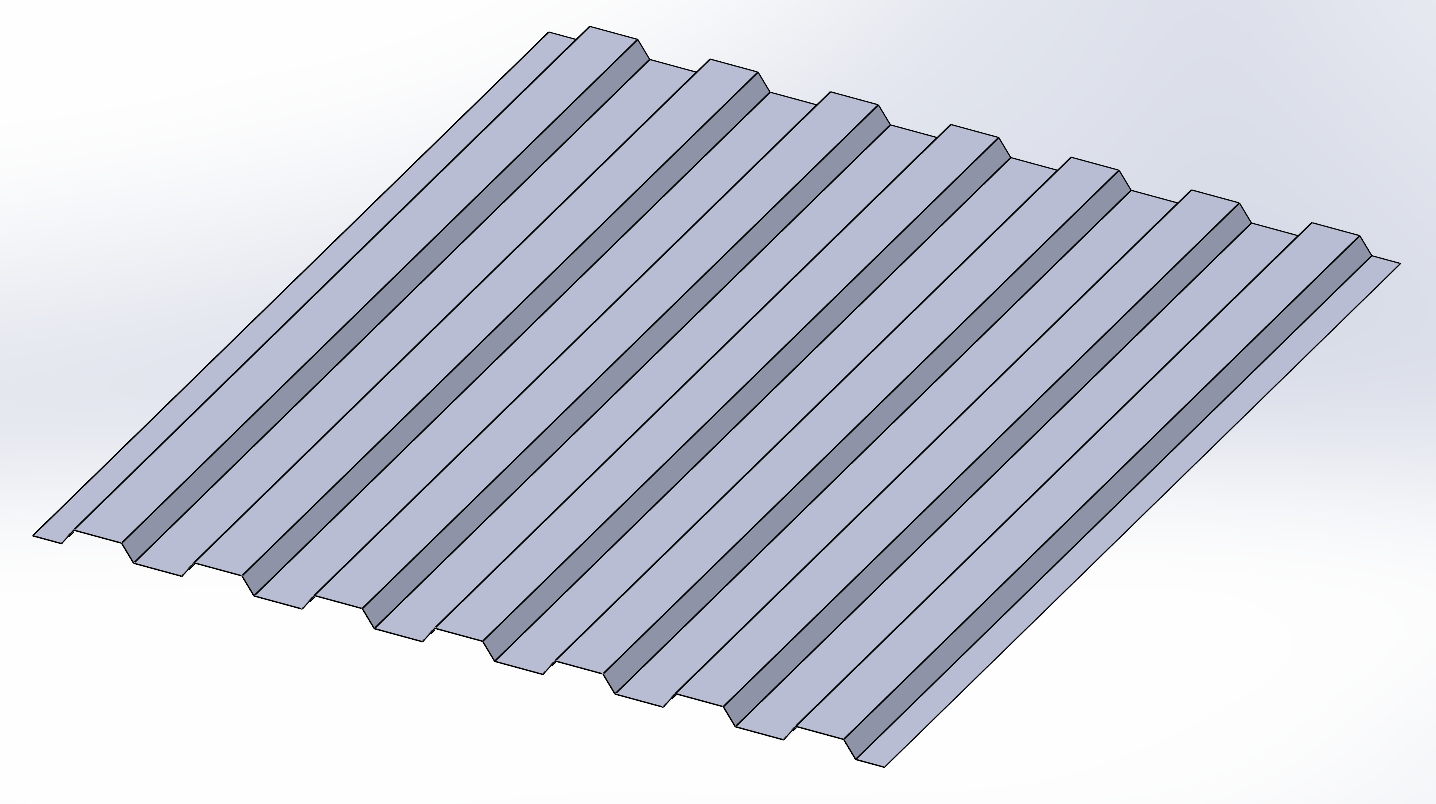

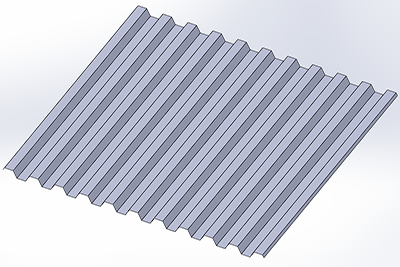

Roofing system roll forming machine is used in an extensive range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile panel, step tile, glazed tiles, metal deck panel, standing seam panel, K span panel and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

The normal thickness range of roof panel roll forming machine is 0.2mm-0.8mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave.

The standard machine speed can reach about 20M/min, if the capacity is big, we can make the machine speed which can reach 25-30M/min. And some customer they require the thickness of the roofing sheet is 1.2mm, it is ok too. If you want learn more of this kind of machine, choosing our company is your best option.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-